What is wrought magnesium alloy?

Plastic Deformation Magnesium Alloy

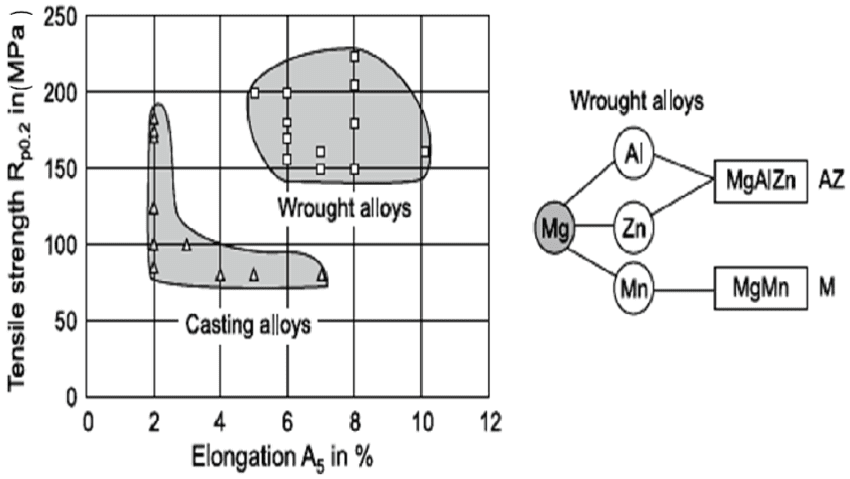

Among wrought magnesium alloys, the commonly used alloy systems are Mg-Al-Zn system and Mg-Zn-Zr system.

Mg-Al-Zn deformation alloys generally belong to deformable materials with medium strength and high plasticity. And the content of aluminum in magnesium is 0-8%.

Typical alloys are AZ31, AZ61 and AZ81 alloys. Because Mg-Al alloy has good comprehensive properties of strength and plasticity. And the price is relatively low, it is the most commonly used alloy series.

Mg-Zn-Zr series alloys are generally high-strength materials. Its deformability is not as good as that of Mg-Al alloy, and it is generally produced by extrusion process.

The typical alloy is ZK60 alloy. High-strength wrought magnesium alloys are also Mg-Mn series. Its main advantage is excellent corrosion resistance and weldability. But poor casting performance, large shrinkage, hot cracking tendency, and less application. In addition, the addition of elements such as Nd, Th, Yb, Sc and Mn can significantly improve the corrosion resistance of wrought magnesium alloys.

At present, the plastic forming process of magnesium alloys is mainly forging and extrusion. A small amount of which is formed by rolling, and hot working methods are required. Therefore, deformation temperature is an important parameter, while deformation rate and stress state are also important considerations.

Forging forming

Magnesium alloy forging performance depends on three factors: the alloy’s solidification temperature, deformation rate and grain size.

In order to ensure good processing performance, forgeability of AZ and ZK series magnesium alloy billets or billets must be used. These two series of alloys can obtain satisfactory grain size by adding grain refiners and alloying elements.

However, the grain size of the casting structure generally does not meet the forging requirements. The ingot must be squeezed to obtain the grain size required for forging, and then forged at a high variable rate.

Magnesium alloys are forged in the range of 55°C below their solidus temperature. If the forging temperature is too low, cracks may be formed. Hydraulic presses and low-speed mechanical presses are commonly used equipment for die forging.

Extrusion

Magnesium alloy can be extruded into various tubes, bars and profiles. Including profiles with recessed corners and dark grooves, thin-walled tubes with large diameters and variable cross-sectional thicknesses, and other difficult-to-process products.

The extruded material is also AZ and ZK series magnesium alloy, and the temperature is generally controlled between 300°C and 460°C. The choice of specific temperature is also related to specific alloy grades and extrusion shapes. Because magnesium generates a lot of heat during the deformation process, it must be sufficiently cooled during the extrusion process. Otherwise, the alloy temperature may exceed the solidus temperature and cause cracking.

Roll forming

Magnesium ingots cast into a flat shape with rounded edges can be used for rolling thick and thin plates. Generally, the thickness of magnesium alloy thick plate ranges from 11.0mm to 70mm, and the thickness of thin plate ranges from 0.8mm to 10mm. The cold rolling performance of magnesium alloy is not good. Generally, thick plates can be directly produced on hot rolling mills, while thin plates are generally produced by cold rolling and warm rolling.

During the hot rolling of magnesium alloy, on the one hand, it is necessary to ensure that the as-cast structure is fully deformed to achieve the purpose of improving the structure, so there must be a certain amount of deformation.

In addition, since the polycrystalline magnesium alloy has a few slip systems, the grains are not prone to macroscopic yielding and are prone to large stress concentrations at the grain boundaries, and the alloy is prone to intergranular fracture. The experimental study found that the first deformation of the billet is controlled at a reduction of s=30%.

Magnesium alloy sheets are generally annealed and heat treated after rolling, and the processed structure will recrystallize. The annealing temperature should be chosen within the range close to the complete recrystallization temperature.

Superplastic deformation

Superplasticity means that crystalline materials exhibit large strains when stretched. Existing research results show that magnesium alloys not only have high plasticity under certain conditions. And even obvious superplasticity appears.

When the grain is refined to a certain degree (about 10-6m), the magnesium alloy can obtain relatively superplasticity. Usually superplasticity mainly occurs at high temperature (approximately equal to 0.7Tm, Tm is the melting point of the material), and the strain rate is relatively low, which is limited in industrial production.

Langdon proposed two necessary conditions for superplastic deformation:

- Local necking is restricted;

- The interconnection within the cavity is suppressed. At present, high strain rate superplastic forming and low temperature superplastic forming are used to obtain fine grains.

Among them, equal channel angular extrusion technology is a method of low-temperature superplasticity, which can make the elongation of AZ91 magnesium alloy reach 675% at a temperature of 200°C.