Characteristics of zinc alloy

Types and composition of zinc alloys

Zinc alloy is an alloy based on zinc and other elements. Commonly added alloying elements are aluminum, copper, magnesium, cadmium, lead, titanium and so on.

Zinc alloy has low melting point and good fluidity. Easy to weld, braze and plastic process. It is resistant to corrosion in the atmosphere, and the waste material is easy to recycle and remelt. However, the creep strength is low, and natural aging is easy to cause dimensional changes.

Prepared by melting method, die-casting or pressure-processed into material.

Zinc alloys can be divided into cast zinc alloys and wrought zinc alloys according to the manufacturing process. Cast zinc alloy has good fluidity and corrosion resistance, and is suitable for die-casting instruments, auto parts shells, etc.

What is the characteristics of zinc alloy

- Relatively large.

- Good casting performance, it can die-cast precision parts with complex shapes and thin walls, and the surface of the castings is smooth.

- Surface treatment can be carried out: electroplating, spraying, painting, polishing, grinding, etc.

- When melting and die-casting, it does not absorb iron, does not corrode the pressure, and does not stick to the mold.

- It has good mechanical properties and abrasion resistance at room temperature.

- Low melting point, melting at 385℃, easy to die-casting.

What is the types of the zinc alloy

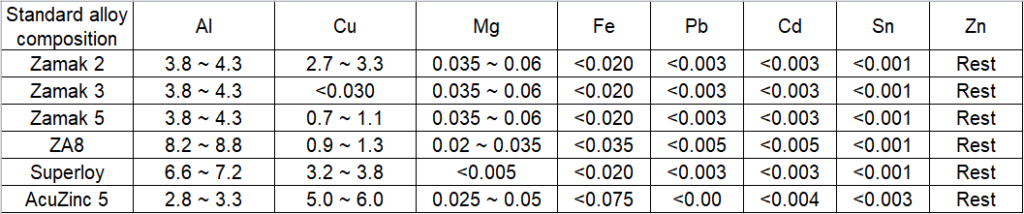

Traditional die-cast zinc alloys are No. 2, 3, 4, 5, and No. 7 alloys, and No. 3 zinc alloy is the most widely used. In the 1970s, high-aluminum zinc-based alloys ZA-8, ZA-12, and ZA-27 were developed.

Zamak 3: Good fluidity and mechanical properties.

Used in castings that do not require high mechanical strength, such as toys, lamps, ornaments, and some electrical devices.

Zamak 5: Good fluidity and good mechanical properties.

Used in castings that have certain requirements for mechanical strength, such as auto parts, electromechanical parts, mechanical parts, and electrical components.

Zamak 2: Used for mechanical parts that have special requirements for mechanical properties, high hardness requirements, good wear resistance, and general dimensional accuracy requirements.

ZA8: Has good impact strength and dimensional stability, but poor fluidity.

Applied to die-casting workpieces with small size, high precision and mechanical strength requirements, such as electrical devices.

Superloy: It has the best fluidity and is used for die-casting thin-walled, large-sized, high-precision, and complex-shaped workpieces, such as electrical components and their boxes.

Different zinc alloys have different physical and mechanical properties, which provides a choice for die casting design.

Zinc alloy types according to the manufacturing process

Zinc alloys can be divided into cast zinc alloys and wrought zinc alloys according to the manufacturing process. The output of cast alloys is much greater than that of deformed alloys.

Cast zinc alloys are divided into pressure casting zinc alloys (solidified under applied pressure) and gravity casting zinc alloys (solidified only under gravity) according to different casting methods.

Die casting zinc alloy

Die casting zinc alloy: Since this alloy was used in the automobile industry in 1940, the output has increased dramatically. About 25% of the total zinc consumption is used to produce this alloy.

Advanced applicable technologies are continuously adopted and developed rapidly. The most commonly used alloy system is the Zn-Al-Cu-Mg system. Certain impurities obviously affect the properties of die-cast zinc alloys.

Therefore, the content of impurities such as iron, lead, cadmium, tin is extremely strict, and the upper limits are 0.005%, 0.004%, 0.003%, 0.02%, respectively. Therefore, high-purity zinc with a purity greater than 99.99% should be used as raw material for die-cast zinc alloys.

Gravity casting zinc alloy

It can be cast in sand, plaster mold or hard mold. This kind of zinc alloy not only has the characteristics of general die-cast zinc alloy, but also has high strength and good casting performance.

The cooling rate has no obvious influence on the mechanical properties, and the residual and waste materials can be recycled. The gate is simple, insensitive to overheating and remelting, has low shrinkage, less pores, can be electroplated, and can be finished by conventional methods.

In addition to the traditional varieties of wrought zinc alloys used in the wrought zinc alloy industry, Zn-Cu-0.1Ti and Zn-22Al alloys have appeared. After the former alloy is rolled, due to the TiZn15 intermetallic compound dispersed particles arranged in rows along the rolling direction, the grain boundary movement can be hindered.

Which zinc alloy to choose

Mainly consider from three aspects

- The purpose of the die casting itself and the performance requirements that need to be met. include:

(1) Mechanical properties and tensile strength are the maximum resistance when the material breaks;

Elongation is a measure of brittleness and plasticity of materials;

Hardness is the resistance of the surface of a material to plastic deformation caused by hard objects or friction.

(2) Working environment status: working temperature, humidity, medium contacted by the workpiece and air tightness requirements.

(3) Precision requirements: achievable precision and dimensional stability. - Good process performance:

(1) Casting process;

(2) Mechanical processing technology;

(3) Surface treatment technology. - Good economy: the cost of raw materials and the requirements for production equipment (including smelting equipment, die-casting machines, molds, etc.), and production costs.

Zinc alloy composition

The role of elements in alloys

Among the alloy components, effective alloying elements: aluminum, copper, and magnesium; harmful impurity elements: lead, cadmium, tin, and iron.

Aluminum

effect:

Aluminum rod

Aluminum rod

① Improve the casting performance of the alloy, increase the fluidity of the alloy, refine the grains, cause solid solution strengthening, and improve the mechanical properties.

② Reduce the ability of zinc to react to iron and reduce the erosion of iron materials such as gooseneck, mold and crucible.

The aluminum content is controlled at 3.8 ~ 4.3%. Mainly considering the required strength and fluidity, good fluidity is a necessary condition for obtaining a complete, accurate size and smooth surface casting.

Copper

effect:

- Increase the hardness and strength of the alloy;

- Improve the wear resistance of the alloy;

- Reduce intergranular corrosion.

Hardware copper sleeve

Hardware copper sleeve

unfavorable: - When the copper content exceeds 1.25%, the size and mechanical strength of the die casting will change due to aging;

- Reduce the extensibility of the alloy.

effect:

① Reduce intergranular corrosion

② Refine the alloy structure to increase the strength of the alloy

③ Improve the wear resistance of the alloy

unfavorable:

① When the magnesium content is> 0.08%, hot brittleness, reduced toughness and fluidity will occur.

② It is easy to oxidize and lose in the molten state of the alloy.

Impurity elements: lead, cadmium, tin

It makes the intergranular corrosion of zinc alloys very sensitive, accelerates its own intergranular corrosion in a warm and humid environment, reduces mechanical properties, and causes dimensional changes of castings.

When the content of impurity elements of lead and cadmium in the zinc alloy is too high, the surface quality of the workpiece is normal when the workpiece is just die-casted, but after a period of storage at room temperature (eight weeks to several months), blisters appear on the surface.

Impurity element: iron

① Iron reacts with aluminum to form Al5Fe2 intermetallic compound, which causes the loss of aluminum and forms dross.

② Hard spots are formed in die castings, which affect post-processing and polishing.

③ Increase the brittleness of the alloy.

The solubility of iron in the molten zinc increases with the increase in temperature. Every change in the temperature of the molten zinc in the furnace will cause the iron to be supersaturated (when the temperature drops) or unsaturated (when the temperature rises).

When the iron element is supersaturated, the supersaturated iron will react with the aluminum in the alloy, resulting in an increase in the amount of dross. When the iron element is not saturated, the corrosion of the alloy to the zinc pot and gooseneck materials will increase to return to the saturated state. A common result of the two temperature changes is the final consumption of aluminum and the formation of more scum.