What is the advantage of magnesium alloy?

What is the difference between magnesium alloy and aluminum alloy?

Advantage of magnesium alloy

Compared with other structural materials, magnesium alloy has the following characteristics:

- Light weight: Magnesium metal is the lightest metal among all industrial metals. Calculated by ρ=1.8 g/cm3, it is similar to plastics, 30% lighter than aluminum, and 1/4 of iron.

- High specific strength: higher than aluminum alloy and steel, specific stiffness is close to aluminum alloy and steel, and has a certain bearing capacity.

- Large elastic modulus: good rigidity, not easy to deform after long-term use.

- It has good castability and dimensional stability, good cutting performance, easy processing, and low scrap rate, thereby reducing production costs. Similar to other metals, magnesium alloys can be assembled and joined in several different ways. Several of the most common methods are welding, riveting, gluing, and bolting.

It has no impact on the environment. Magnesium metal and its alloys are environmentally friendly materials and have no pollution to the environment. The recycling rate of waste materials is as high as 85%. Since recycling consumes less energy, the cost is only the price of corresponding new materials. About 4% of the total.

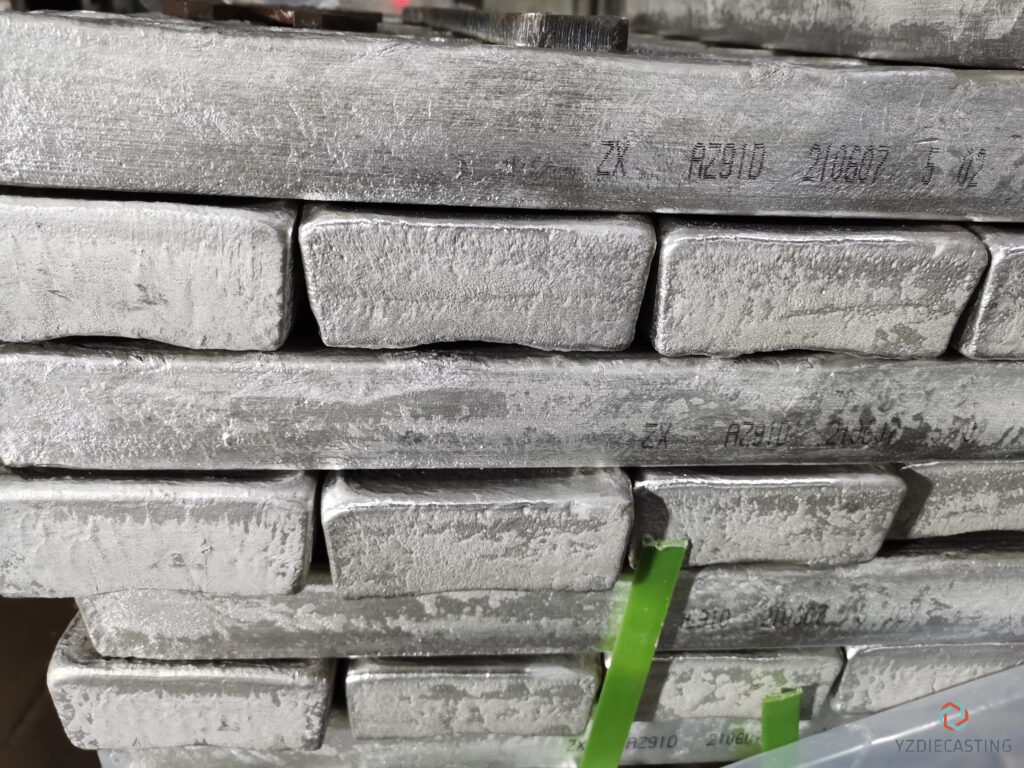

Magnesium alloy has good formability and good mold filling ability. The solidification speed after mold filling is faster, and the thermal shock to the die casting mold is small. It can be used for die-casting thin-walled parts and is not prone to defects such as hot cracking and under-casting. With good die-cast ability, most of the existing magnesium metal products are die-casting parts, thus realizing large-scale and high-efficiency industrial production.

It has good plasticity at high temperature, so various specifications of bars, tubes, profiles, forgings, die forgings and plates, as well as stamping parts (deformed magnesium alloy category) can be obtained by pressure processing.

Anti-electromagnetic

Good anti-electromagnetic interference, good shielding, and its excellent comprehensive mechanical properties can be widely used in 3C products (3C products in a narrow sense include computer information, telecommunications, and consumer electronics).

Advantage compare with aluminum

Good vibration absorption and impact resistance. The amount of vibration reduction is greater than that of aluminum alloy and cast iron. It can reduce noise when used in the shell. It can reduce vibration when used in seats and rims, and improve the safety and comfort of the car. Therefore, it is used in the automotive industry. Very broad application prospects.

High-purity magnesium alloy also has excellent corrosion resistance and good electrical and thermal conductivity. It is widely used in housing parts of electronic products that require heat dissipation, shielding, and electromagnetic radiation protection.

The die-casting temperature of magnesium alloy is lower than that of aluminum alloy die-casting, thereby reducing the thermal fatigue of die-casting molds, shortening the in-mold time of die-casting parts, and the production rate is about 75% faster than that of aluminum alloy. At the same time, the service life of the die-casting mold is prolonged. The service life of the magnesium-alloy die-casting mold is about 3-4 times that of the aluminum alloy mold. Its life span even exceeds 500,000 times.

Mould advantage of die casting

Magnesium alloy basically does not react with iron, and does not corrode the steel crucible and die-casting mold cavity, so the life of the crucible and die-casting mold is prolonged, so that magnesium alloy can not only be die-cast by cold-chamber die-casting machine like aluminum alloy, but also can be used efficiently. Higher hot chamber die casting machine and thixoforming die casting machine die casting.

The shrinkage rate of magnesium alloy is uniform, and the demolding force is 20%-30% lower than that of aluminum alloy. Magnesium alloy die castings not only have high dimensional accuracy, but also the cleaning energy consumption (secondary processing) of their die castings is less than 60% of aluminum alloy die castings.