Mold temperature controller, Pickup robot, automatic sprayer, automatic pressure feeder

What is die casting peripheral equipment?

Mold temperature controller 1

Maintaining the stability of the mold temperature in the die-casting production is conducive to the constant production rhythm and obtaining high-quality castings, and it is also conducive to prolonging the life of the mold. Compared with aluminum alloy, magnesium alloy has a smaller heat capacity. Therefore, unlike most die-casting molds in aluminum alloy die-casting. Which often require water cooling, magnesium alloy molds often need to be heated to meet normal production.

Especially when producing some thin-walled parts. In order to heat the mold, some die-casting plants often use a torch heating method. Which is not suitable for magnesium alloys. Because it is difficult to make the temperature of the mold uniform. The life of the mold will be prone to cracks due to the impact of overcooling and overheating.

Moreover, due to the low latent heat of magnesium alloy. In order to maintain good filling conditions and stable production when producing thin-walled parts. It is usually necessary to continuously heat the mold to maintain the balance of the mold temperature. In the die casting of magnesium alloy, the most ideal heating method is to use a mold temperature machine to heat the mold.

Mold temperature controller 2

The mold temperature machine utilizes a heat-conducting medium with high thermal conductivity. Which can transfer heat to the mold in a short period of time. There are two types of commonly used mold temperature controllers. One type is hot water mold temperature controller, and the other is hot oil mold temperature controller.

Due to the limitation of the boiling point of water, in the case of sealed heating, the maximum use temperature of the hot water mold temperature machine can only reach between 140°C and 160°C. As magnesium liquid encounters water, it will react fiercely and cause an explosion. The leakage of high-pressure cooling water in the mold may cause an explosion.

In addition, the temperature of the mold during magnesium alloy die-casting is usually maintained between 180°C and 280°C. Therefore, hot water Mold temperature controllers are rarely used in magnesium alloy die-casting.

The hot oil mold temperature controller is commonly used in magnesium alloy die-casting. The boiling point of the heat transfer oil is higher, and the use temperature is much higher than that of water. The heating of the mold is more uniform and constant. The use temperature of the hot oil mold temperature machine can reach 300 ℃ or more. .

Pickup robot

The pick-up manipulator is also called the automatic pick-out machine. After the die-casting of the die-casting machine is completed and the mold opening is in place, the casting is automatically taken out by the take-out manipulator and placed in the specified position.

The automation of the die-casting production can be realized through the connection of the pick-up manipulator and the die-casting machine. Reduce the labor intensity of the operator, reduce the auxiliary time, and maintain the stability of the production cycle.

And can be combined with trimming machine, etc., directly place the taken out die castings on the trimming machine for trimming and other operations, which greatly improves production efficiency.

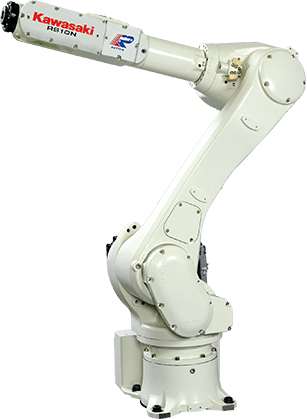

There are two commonly used forms of pickup robots, one can be called an industrial robot, as shown in the following figure:

This kind of manipulator is characterized by flexible operation and large range of motion. It can be programmed to control the actions of the manipulator, which can realize more complex movements, and can realize complex movements such as cooling and edge trimming. High positioning accuracy and good repeatability.

On some models, the pickup and spraying manipulators can be integrated, which simplifies the operation and saves time, but the price is also more expensive.

Another manipulator is shown in the figure below:

This kind of pickup manipulator has simple structure and convenient operation, and has the following characteristics:

1) Specially driven machinery, with balanced and fast arm movements.

2) The arm rotates by 90%, and the mechanical body is fixed on the side of the seat plate, which does not affect the space for assembling and disassembling the mold.

3) The clamping arm has a special structure, the removal position is accurate, the clamping diameter can be adjusted with the actual size of the casting, the three-point clamping jaws are stable and reliable, and durable.

4) It has a waterproof, dustproof, and splash-proof design, and has a long service life.

5) Air-driven, high-speed operation and easy maintenance.

6) The number of products taken out to confirm the inspection can be selected and set with the switch.

Automatic sprayer

The automatic sprayer is a device that sprays the release agent (also called the release agent) into the die-casting cavity in a mist form by means of compressed air. The following picture shows the appearance of two automatic sprayers, which have the following characteristics:

1. The spray volume is controlled by the time and flow valve, the atomization is uniform, and the adjustment is easy

2.The spray volume of the movable die of the die-casting type (mold) can be adjusted individually.

3. Copper tube design, direction can be set freely, any complex (mold) tool can be used.

4.The copper tube holder is easy to replace, and the number of copper tubes can be increased or decreased at will.

5. It is equipped with a separate blowing copper pipe, which can blow dry the residual release agent.

6.The rotation angle is 90o.

7.When the air source stops, the ascent limit position can be automatically locked.

The automatic sprayer produced by Shangfu Industrial Co., Ltd. uses a water-based release agent, which is safer to use.

YZDIECASTING automatic die casting production: https://youtu.be/WYYa1fQlPo4