The effect of high-speed cooling on the phase diagram

The effect of the physical properties of magnesium alloy on the performance of die casting

Under die-casting conditions:

Due to the high flow rate, the strong cooling capacity of the metal mold, and the fast cooling rate. The eutectic point in the binary system phase diagram shifts to the direction of the thermally stable component.

For Al alloys, it moves in the direction of increasing Si, and for Mg alloys, it moves in the direction of increasing Mg. This shift can make Al partial hypoeutectic alloys become solid-solution single-phase alloys. Part of the Al hypereutectic alloy becomes a hypoeutectic alloy. Mg alloys are just the opposite. Some solid solution alloys become hypoeutectic alloys, and some hypoeutectic alloys become actual hypereutectic alloys. Generally speaking, a high cooling rate increases the content of Mg alloy eutectic, which is beneficial to casting.

In addition, compare the difference between the melting point and the eutectic temperature of pure magnesium and pure aluminum. It shows that magnesium alloys are easy to cast, with a value of 212°C for magnesium and 73°C for aluminum.

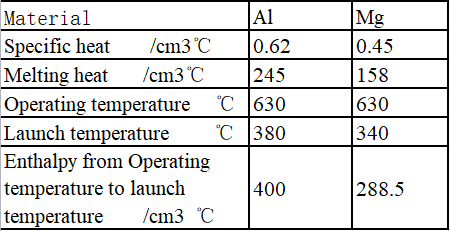

Heat Enthalpy

The heat from the working temperature to the solidification temperature determines the time for the molten metal to maintain castability under the same thermal conductivity. Therefore, this heat is used as a measure of the maximum possible filling time. The qualitative formula of filling time T and enthalpy from working temperature to solidification temperature is:

Tm;Ta=Qm/Qa then: Tm=QmTa/Qa

Compare CD=MgAl9Znl and GD-AlSi12(Cu), then Tm=130.5/275Tal=0.654Ta

That is, the time required to fill the same cast magnesium alloy is 65% of the aluminum alloy.

The influence of molten metal viscosity and pouring speed on filling

Using Reynolds number to express properties, it not only takes into account the geometry of the runner. And also consider the flow resistance due to speed friction. The viscosity of GD-MgAl9Znl and GD-AlSi12(Cn) is also compared, and the pouring speed can be obtained qualitatively. First of all, the flow characteristics of the two are the same, so as a criterion, the Reynolds numbers of the two must be equal.

Rea=Rem Re=WDh/V or medium

Re-Reynolds number

W-average pouring speed

Dh-liquid flow trough diameter

V——Viscosity at pouring temperature

Known: Va=5.310-6 m2/S Vm=6.6510-6 m2/S

Substituting into the equation: Wm=Wa*6.65/5.3 Wm=1.25Wa

Wm: Average casting speed of aluminum alloy

Wa: Average casting speed of magnesium alloy

The above conclusions indicate that the average speed of filling the cavity with magnesium alloy is about 1.25 times that of filling the cavity with aluminum alloy.

Air and Air hole

The pores exist in the casting in various ways. One way is due to the precipitation of gas from the liquid during the cooling process, mainly H2. Others are brought in air due to pouring. Magnesium has a strong ability to dissolve hydrogen. Even if there is only a small amount of water on the ingot, it may absorb hydrogen through the reduction of water. However, nitrogen produces nitrides and oxygen produces oxides. Therefore, the influence of the atmosphere is small, and the temperature of the air is related to the gas content. That is, the magnesium block must be thoroughly dried before being put into the furnace for melting.

Stickiness

The sticking tendency refers to the tendency of the casting alloy to adhere to the mold. This phenomenon has a great influence on the die casting process.

- The melting degree of the alloy to the casting material. Magnesium alloy has its advantages in this respect, the main alloying element of general die steel. Except for nickel, others such as iron, cobalt, manganese, aluminum, and calcium are insoluble or only slightly dissolved in magnesium alloy, so mold sticking will not occur.

- The strength of the casting at the demoulding temperature. At about 300°C, the strength of magnesium alloy is about half that of aluminum alloy. As long as there is no problem on the surface of the cavity, the ejection is balanced, and no shear stress is generated. Such thermal strength is sufficient to ensure that the casting is ejected from the mold.

- The adhesion coefficient between the casting and the cavity surface. When the roughness between the friction pairs is 30/um and the friction speed is 0.1m/s. The adhesion coefficient between aluminum and steel is 0.1, and The magnesium-steel ratio is only 0.05.

can be seen that magnesium alloys have great advantages. Therefore, magnesium die castings can use the smallest draft angle and obtain higher precision.