What is cast aluminum alloy

Application and classification of aluminum casting

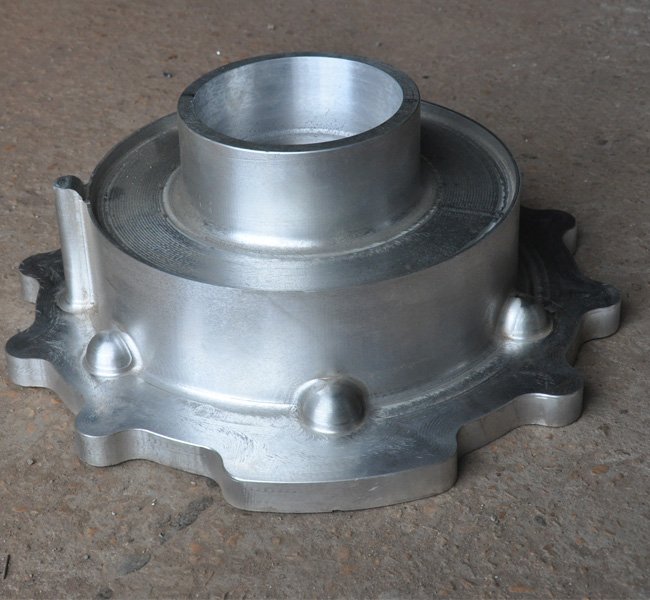

Casting aluminum alloy is an aluminum alloy in which molten metal is filled into a mold to obtain various shapes of parts. It has the advantages of low density, high specific strength. Good corrosion resistance and casting processability, and less restricted by the structural design of parts.

It is divided into Al-Si and Al-Si-Mg-Cu-based medium-strength alloys. Al-Cu-based high-strength alloy. Corrosion resistant alloy based on Al-Mg. Al-Re-based heat-strength alloy.

Most of them need heat treatment to achieve the purpose of strengthening the alloy. Eliminating the internal stress of the casting, stabilizing the structure and the size of the parts.

It is used to manufacture beams, gas turbine blades, pump bodies, pylons, hubs, intake lips and engine casings. It is also used in the manufacture of automobile cylinder heads, gearboxes and pistons, instrument housings and turbocharger pump bodies.

Overview of aluminum casting

The aluminum alloy used for the required parts is directly obtained by casting process. It is required to have ideal castability. Good fluidity, small shrinkage, hot cracking and cold cracking tendency, small segregation and gas absorption.

The element content of cast aluminum alloys is generally higher than that of corresponding deformed aluminum alloys, and most alloys are close to the eutectic composition.

From 1905 to 1925, European and American countries carried out research on industrial aluminum alloys on the basis of studying the phase diagrams of aluminum alloys.

The aluminum-nickel alloy was initially studied, but its casting performance was poor. So nickel failed to become the main strengthening element. Later, he studied the addition of copper, magnesium, manganese, silicon and other elements to aluminum, and obtained relatively ideal properties. Therefore, some binary and multi-element cast aluminum alloys were developed. Among them, the famous silicon aluminum alloy was used around 1920. In industry.

Application of cast aluminum alloy

Cast aluminum alloy has good casting properties and can be made into parts with complex shapes; it does not require huge additional equipment. It has the advantages of saving metal, reducing costs, and reducing working hours, and is widely used in the aviation industry and civil industry.

It is used to manufacture beams, gas turbine blades, pump bodies, pylons, hubs, intake lips and engine casings. It is also used in the manufacture of automobile cylinder heads, gearboxes and pistons, instrument housings and turbocharger pump bodies.

Classification of cast aluminum alloy

Modern cast aluminum alloys can be divided into 4 series according to the main added elements. Aluminum-silicon series, aluminum-copper series, aluminum-magnesium series and aluminum-zinc series.

For these 4 series, all countries have corresponding alloys and alloy grade marks. China adopts the ZL+3 digit notation method. The first digit indicates the alloy system, among which: 1 indicates the aluminum-silicon alloy system, 2 indicates the aluminum-copper alloy system, 3 indicates the aluminum-magnesium alloy system, 4 indicates the aluminum-zinc alloy system, and the second , Three digits indicate the alloy serial number.

According to the characteristics of the alloy, it can be divided into: heat-resistant cast aluminum alloy. Airtight cast aluminum alloy, corrosion-resistant cast aluminum alloy and weldable cast aluminum alloy

Aluminum-silicon alloy

Usually the silicon content is 4% to 13%, which is also called “silico-alumina” alloy. It has the best casting performance, minimal crack tendency, low shrinkage, good corrosion resistance and air tightness, and sufficient mechanical properties and welding performance.

Although the industrial application of this series of alloys is later than that of aluminum-copper series alloys, it was discovered in 1920 that it can be modified to improve the structure and properties of this series of alloys, and broaden the scope of use. 50% of cast aluminum alloy.

Aluminum-silicon alloys can be divided into eutectic, hypoeutectic, hypereutectic and complex eutectic alloys with copper, magnesium, and manganese added. ZL102 alloy is a typical binary eutectic alloy, the eutectic temperature is 577 ℃, the eutectic composition is 12.6% Si, 1.6% Si is dissolved in α solid solution at eutectic temperature, and about 0.05% Si is dissolved at room temperature. The β phase is a solid solution in which aluminum is dissolved in silicon, and its solubility is extremely small, so the eutectic structure is composed of α+Si two phases.

In the structure of multi-element alloys, in addition to α and silicon. There are phases such as θ (CuAl2) and W (AlxMg5Si4) (see aluminum alloy phases). Aluminum-silicon alloys containing copper can be strengthened by heat treatment, but have poor corrosion resistance. The shape of the silicon phase in the alloy has a significant effect on the strength and plasticity. Through modification (adding sodium or antimony in the melt). The silicon phase is spheroidized, and the structure and properties of the alloy are improved. The coarse primary silicon in hypereutectic alloys is harmful to mechanical properties and cutting performance. Phosphorus is often added to form AlP compounds to refine primary silicon and reduce its harmful effects.

Aluminum copper alloy

It is the earliest industrial cast aluminum alloy. This series alloy has high strength and thermal stability, but poor castability and corrosion resistance.

The copper content is generally lower than the solubility limit of copper in aluminum (5.85%), and there is no eutectic in the equilibrium structure. Under non-equilibrium conditions, a small amount of eutectic may appear. After solution treatment, the solid solution is supersaturated, and the aging strengthening effect can be obtained.

The addition of manganese and titanium to the alloy can refine the grains, supplement strengthening and improve corrosion resistance.

Aluminum-magnesium alloy

This series alloy has high strength, best corrosion resistance, low density and good air tightness. The magnesium content of aluminum-magnesium binary casting alloy is as high as 11.5%, and the magnesium content in the multi-element alloy is generally about 5%.

The structure of the alloy is composed of α+β (Mg5Al8) phase, and the strengthening effect of heat treatment is not obvious, mainly solid solution strengthening. When β(Mg5Al8) phase precipitates in a network shape along the grain boundary, the corrosion resistance and mechanical properties deteriorate.

In order to prevent the β (Mg5Al8) phase from precipitating along the grain boundary, it is mostly used in a solid solution state. Adding silicon and manganese to the alloy can improve the fluidity of the alloy.

Aluminum zinc alloy

This alloy has the characteristics of quenched structure in the as-cast state. High strength can be obtained without heat treatment. However, the density of the alloy is so high that it is not suitable for making aircraft parts.

This alloy is made by adding zinc on the basis of silicon aluminum alloy, so it is also called “zinc silicon aluminum alloy”

Aluminum alloy refining technology-1

The refining of aluminum alloy is mainly to remove the gas and non-metallic inclusions in the alloy liquid. The gas in aluminum alloy is mainly hydrogen (accounting for more than 85%), and the inclusions are mainly alumina. Since the saturation solubility of hydrogen in liquid and solid aluminum alloys differs by nearly 20 times, hydrogen is easily precipitated during the solidification of aluminum alloys, causing pinholes in castings.

Inclusions and gases interact. When the hydrogen content in 100 g of aluminum alloy liquid is higher than 0.1 ml in industrial pure aluminum, pores will appear, while in high-purity aluminum, each 100 g of aluminum alloy liquid contains hydrogen. When the volume is as high as 0.4 ml, stomata will appear. It can be seen that degassing must be slag removal, and slag removal is the basis of degassing.

Aluminum alloy refining technology-2

The commonly used refining agent for aluminum alloy is hexachloroethane or chloride salt. This refining agent has very good degassing and slag removal effects, but it is not conducive to environmental protection and is gradually being replaced by non-toxic refining agents. Researchers at home and abroad have developed two types of effective refining methods, namely the rotating impeller method (RID method) and the spray flux method (FI method).

Rotating impeller method (RID method) is to pass inert gas into the alloy liquid. The large bubbles are broken into small bubbles with a diameter of about 0.5 mm by rotating and cutting the impeller. They are evenly distributed in the alloy liquid and rise slowly to improve the degassing effect.

Flux injection method (FI method) is to spray powdered flux uniformly into the alloy liquid with an inert gas as a carrier. Increase the contact area between the flux and the alloy liquid, and enhance the slag removal effect. At the same time, the flux changes the properties of the interface between the bubbles and the alloy liquid, and improves the hydrogen removal effect of the inert gas.

At present, the refining method with better effect is to combine the above two methods. Namely the rotary injection method. Which sprays powdery flux into the alloy liquid on the basis of the rotary impeller method.