What is Investment casting of magnesium alloy?

What is Lost foam casting of magnesium alloy?

Investment casting

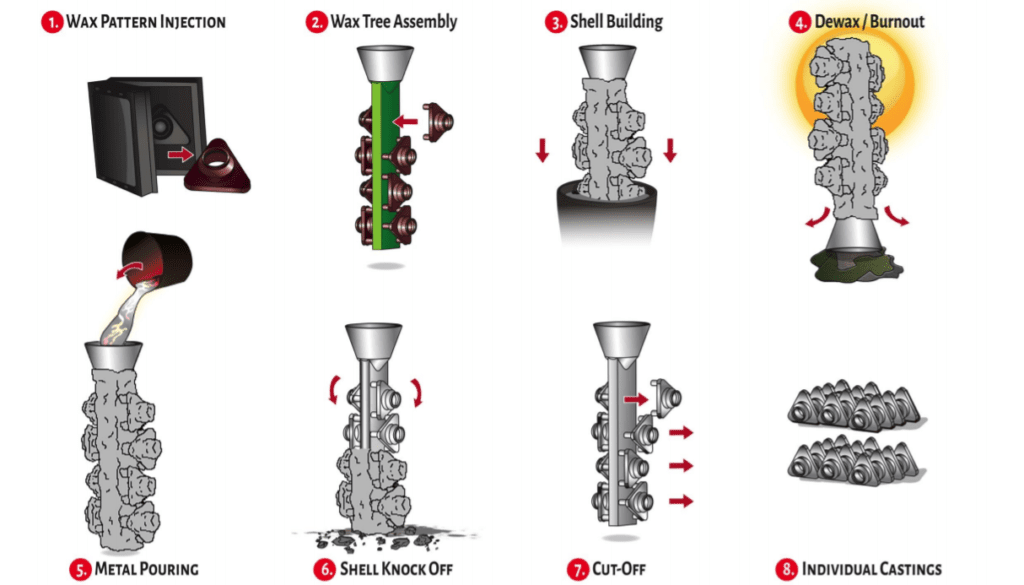

What is investment casting?

Investment casting is one of the most advanced casting technologies in the world. In principle, investment casting is suitable for the preparation of small-volume and high-precision castings. It has been used to produce aluminum alloys and even nickel-based super alloys.

In the development process of magnesium alloy castings, some workpieces have complex structures, some parts have very thin wall thicknesses. And have strict requirements on surface roughness and dimensional tolerances, so investment casting can be used for production.

The advantage of investment casting

The use of investment casting method to produce castings has the characteristics of no need to take molds, no cores, and no parting surfaces. Therefore, the dimensional accuracy and surface roughness of its castings are close to investment castings.

In addition, investment casting provides a sufficient degree of freedom for the design of the casting structure. The original assembled components of multiple parts can be integrated into one piece by splitting and molding. So that many complex parts can be produced economically.

The disadvantage of investment casting

However, investment casting equipment investment and unit casting cost are high, and the size of the workpiece is limited. In addition, there is a highly active reaction between magnesium and investment casting materials and oxide ceramics for bonding materials, which greatly limits its application.

When producing magnesium alloy thin-walled parts, it is necessary to preheat the mold to fill the thin-walled parts. However, the preheating temperature and the pouring temperature are too high to promote the reaction between the magnesium alloy and the mold. Studies have shown that ZrO2 is a promising mold material when using a low mold preheating temperature.

Lost foam casting

Lost foam casting is a new type of casting technology with almost no margin and precise shaping, and it has many advantages.

For example, the molding sand does not require a binder, and the casting sand falling and sand treatment system is very simple and easy to realize clean production; the casting has no parting surface and draft angle, which can make the structure of the casting high.

The processing and assembly time is reduced, and the cost of castings can be reduced by 10%-30% and so on.

Unique advantages of lost foam casting of magnesium alloy

- At the pouring temperature of magnesium alloy, the decomposition products of the foam pattern are mainly aerosol substances such as hydrocarbons, benzene and styrene. They have a natural protective effect on the liquid magnesium alloy, which is easily oxidized during hedging forming;

- The use of dry sand negative pressure molding avoids the contact of magnesium alloy liquid with moisture in the molding sand and casting defects caused by this;

- Compared with the currently commonly used magnesium alloy die-casting process. Its investment cost is greatly reduced, and the dry sand has good concession to reduce the hot cracking tendency of magnesium alloy during solidification and shrinkage.

The slow and stable filling speed of molten metal avoids the entrapment of gas.

So that the casting can be heat treated to further improve its mechanical properties. Therefore, the lost foam casting of magnesium alloy has a huge application prospect.

Characteristics of the chemical properties of magnesium alloys

The characteristics of the solidification and chemical properties of magnesium alloys. Have caused many problems in the lost foam casting of magnesium alloys, especially insufficient pouring and oxidation and combustion.

Due to the low density and specific heat capacity of the magnesium alloy. The heat required to vaporize the foam pattern comes from the latent heat of the high-temperature liquid magnesium alloy, which hinders the filling. In addition, the crystallization temperature range of magnesium alloy is wide. So the pressure head effect of the molten metal is small when the mold is filled. It is easy to stop the flow prematurely, resulting in insufficient pouring defects.

The chemical reaction of magnesium alloys may be controlled by the use of flame retardants used in the magnesium alloy sand casting industry and the auxiliary use of pattern coatings with high porosity. A controllable atmosphere can also be used to prevent oxidation and combustion during pouring.

In addition, the high-density foam pattern absorbs more heat, produces more liquid and gaseous products. And reduces the fill ability of the magnesium alloy. However, the reducing atmosphere generated by the foam pattern during the pouring process is reduced. And even prevents the oxidation and combustion of the magnesium alloy.

This ensures the safety of the magnesium alloy during the processing and forming process. And also helps to ensure the clean and high-quality magnesium alloy melt.